Greetings from New Hampshire!

We are currently enjoying the gorgeous views and relaxing before the fun and chaos of Reach the Beach, a 200-mile Ragnar relay race begins tomorrow morning. Before driving from Boston to New Hampshire, Team Girls Run Beta (#nbgirlsrunbeta) had the opportunity to tour both the New Balance Global Headquarters and the New Balance Factory located in Lawrence, Massachusetts.

Our group was constantly in awe, learning new things about a brand we each know and love. I started the day a fan of New Balance as their shoes have carried me through countless races over the past few years. But after interacting with a number of their staff today at both locations, I ended the day a passionate consumer. I love that every person we spoke with lit up when talking about their product. I also have a far deeper appreciation for my favorite New Balance shoes since I now realize what goes into making each pair.

Here are five things that I took away from our group visit with New Balance today.

1. New Balance makes 25% of their shoes in the United States! In order for a shoe to be considered “MADE IN THE USA” 70% of the shoe must be made in the United States.

2. The chicken is an important part of New Balance’s history! The first New Balance product was arch support, inspired by the chickens in his yard. He realized that their three clawed foot allowed them to have the perfect balance.

3. Walking the halls of both locations, it is clear that athletes, both professional and everyday, are at the root of everything they do. Whether it is product testing or hosting events, their goal is to help each athlete train and perform better while striving to deliver the highest level of customer satisfaction.

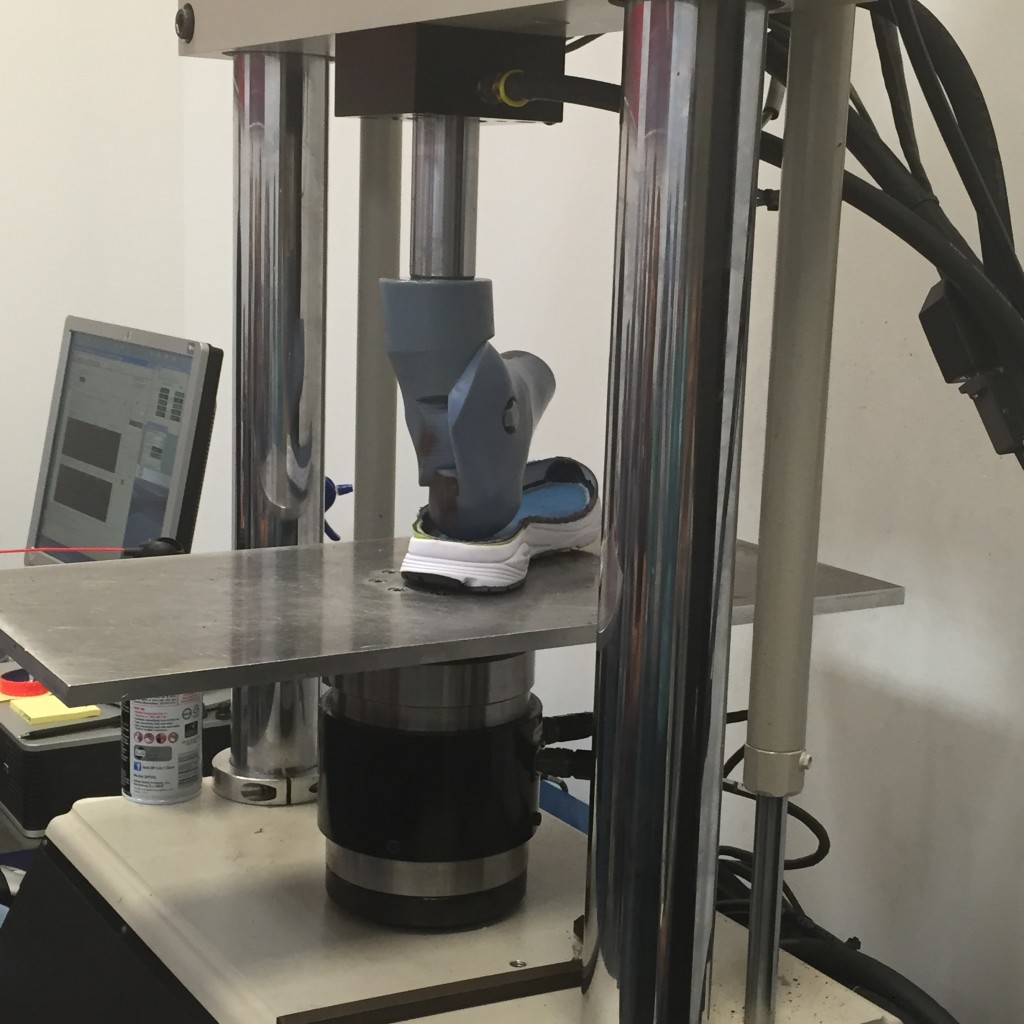

4. At least 28 people touch each shoe and each team manufacturers over 600 shoes per day! The manufacturers at New Balance are truly artists, having an average of 13 years experience building the shoes.

5. The team at New Balance is constantly studying, researching, interviewing and innovating to ensure they are delivering the best product possible to athletes. In New Balance’s Smash Lab they have the ability to put wear and tear on shoes within minutes and days that would often take months of use. They have multiple surfaces including Fenway Stadium dirt, so they can see how shoes respond to impact, use and pressure. We were able to watch foam respond to constant impact and the amount of traction needed for an athlete to perform on surfaces like the courts of Wimbeldon.

Thank you again to the team at New Balance for sponsoring this day and weekend. I know that each of us will appreciate the shoes we lace up tomorrow morning far more now that we’ve seen behind the scenes and understand the love, passion, research and precision that goes into making each one.

Your Turn: We learned today that people can customize their shoes online all the way down to the message embroidered on the tongue! If you were to order a pair, what would your tongue say? Mine would say you’re stronger than you think!

![IMG_4283[1]](http://www.healthyhappierbear.com/wp-content/uploads/2015/09/IMG_42831-1024x1024.jpg)

![IMG_4184[1]](http://www.healthyhappierbear.com/wp-content/uploads/2015/09/IMG_41841-1024x768.jpg)

What a neat experience! Hope the run goes well!

I like that they make 25% of their shoes in the US! I’m curious why they don’t make more of their shoes in the US. Do you know why?

I assume it’s cost but keep in mind no other major shoe brand even reaches this level. I will ask to see if I can get you an answer!

Such a cool tour.